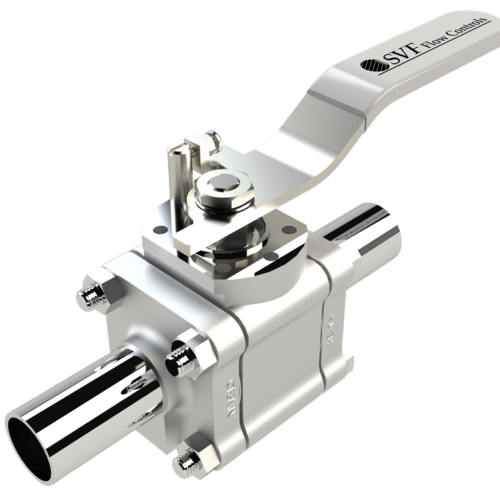

SVF Sanitary Valves

SVF Flow Controls offers a complete line of fully compliant, hygienic ball

valves that meet these stringent guidelines. CleanFLOW TM ball valves are engineered to be a true process piping component to specifically meet the demanding processes found in the pharmaceutical, biotech, semiconductor, cosmetics, foods and other industries. The port opening of the valve’s flow path is dimensionally identical to the adjacent tubing. This “Tube-ID” feature provides predictable flow rates and pressure drops and ensures thorough cleaning and drainability as mandated by ASME-BPE.